Industrial Dehumidifiers

Introducing Industrial Dehumidification Solutions – Newsome and DST Humidity Control

For over 50 years, Newsome has been working in close collaboration with DST Humidity Control to deliver high quality industrial dehumidification solutions across a diverse array of industries in the UK. Our joint expertise in supplying industrial dehumidifiers has made a significant impact in various sectors, providing unmatched humidity support that ensures optimal manufacturing conditions and product quality.

At Newsome, we take pride in offering a wide range of industrial dehumidifier solutions tailored to suit the unique requirements of each industry sector. Our dedicated team of experts is always ready to assist you in finding the ideal dehumidification system for your specific needs.

Whether you need a solution for a large-scale manufacturing facility or a compact dehumidifier for a specialised workspace, we have you covered. contact us today to discover how we can optimise your processes and ensure the highest standards of quality across your operations.

Quick Enquiry

-

Desiccant Dehumidifiers

Efficient Moisture Control for Cooler Climates

Desiccant dehumidifiers are a specialised type of dehumidification system that operates on a different principle compared to traditional refrigerant-based dehumidifiers. They are particularly advantageous in cooler climates or situations where a low dewpoint is required.

Unlike refrigerant dehumidifiers that produce water through condensation, desiccant dehumidifiers do not generate any water during the process. This unique feature allows them to function effectively even in sub-zero temperatures. The core component of a desiccant dehumidifier is the rotor, which is made up of alternating layers of flat and corrugated sheets impregnated with a desiccant, an active drying material.

The rotor is engineered to create numerous axial air channels running parallel through its structure. As air flows through these channels, moisture is transferred in its vapor form between the air and the desiccant. The rotor is typically divided into two air zones separated by seals: the process sector, responsible for around 75% of the dehumidification process, and the reactivation sector, which accounts for the remaining 25%.

The rotor slowly rotates at a rate of approximately 8 to 12 revolutions per hour, driven by a small, geared drive motor. The system air is drawn through the larger process sector, where the rotor material adsorbs moisture from the air. Consequently, the air leaves the dehumidifier in a warm and dry state. The heat gain during this process is primarily due to the energy exchange that occurs during adsorption.

In parallel, a smaller heated air stream, usually fresh air, is pulled through the reactivation sector. This hot air serves the purpose of driving out the moisture that has been adsorbed into the rotor material during the dehumidification process. As a result, the reactivation air exits the rotor in a warm and wet condition and is usually exhausted to the outside.

By allowing these two opposing airflows to pass through the rotor simultaneously, a continuous and automatic dehumidification process is achieved. To control the drying capacity, the reactivation heater power is regulated.

To further enhance system efficiency, a heat recovery or purge sector can be incorporated. This third sector preheats the incoming reactivation air by recovering heat from the rotor material before it reaches the reactivation heater. As a result, less energy is required to heat the reactivation air, and the dry air produced is both drier and cooler compared to the outcomes achieved in traditional desiccant systems.

In summary , desiccant dehumidifiers offer an effective solution for moisture control in cooler climates or when a low dewpoint is necessary. Their unique design and utilisation of desiccant materials allow them to function efficiently even in sub-zero temperatures, making them a valuable asset in various industrial and commercial applications.

-

Refrigerant Dehumidifiers

Efficient Solution for Warm and Humid Conditions

Refrigerant dehumidifiers are the most commonly used type of dehumidifier due to their cost-effectiveness, ease of operation, and suitability for a wide range of domestic and commercial applications. They excel particularly well in warm and humid conditions.

A crucial aspect to understand about refrigerant dehumidifiers is that their performance is directly influenced by the difference between the air’s dry bulb temperature and its dewpoint temperature. The greater this difference, the more effectively the dehumidifier operates.

Operating on a concept similar to that of a portable air conditioning unit, a refrigerant dehumidifier re-arranges the air by passing it across an evaporator coil to cool it and then across a condenser coil to heat it. As a result of this process, the air becomes both warmer and drier.

The cold evaporator coil cools the air to a point where condensation occurs, and the formed moisture condenses on the coil’s surface. This condensed water then drips into a collection tray and is either drained away or gathered in a container at the base of the unit.

As the air surrounding the dehumidifier becomes drier, the dewpoint lowers, meaning that the temperature required to create condensation on the cold evaporator coil also decreases. However, even with an evaporator coil temperature of 0°C, the air’s dewpoint is unlikely to be significantly reduced below 10°C. It’s worth noting that air at 20°C with 50% relative humidity already has a dewpoint below 10°C.

When the dewpoint of the air is already low, the temperature necessary for condensation to occur can drop below freezing. This is when the operating efficiency of a refrigerant dehumidifier is notably reduced. The evaporator coil may start to freeze as airborne water vapor comes into contact with its cold surface. To address this issue, the dehumidifier enters a defrost cycle. During defrosting, hot refrigerant gas from the compressor is directed into the evaporator coil. However, during the defrost cycle, the dehumidifier temporarily stops removing water from the air.

In conclusion, refrigerant dehumidifiers offer an efficient and practical solution for managing humidity in warm and humid conditions. They function effectively by using the principle of condensation on a cold evaporator coil. However, in situations where the air’s dewpoint is already low, their efficiency might be compromised, and a defrosting mechanism becomes necessary to maintain optimal performance. Overall, refrigerant dehumidifiers remain a popular choice for various applications, providing a comfortable and dry environment in diverse settings.

-

Desiccant Drying with Pre-Cooling - Achieving Optimal Moisture Control

In the pursuit of efficient moisture removal, a combination of desiccant drying and pre-cooling using chilled water-cooling coils has proven to be highly effective, especially when the inlet conditions permit. By incorporating cooling coils alongside the desiccant unit, it is possible to achieve dew points as low as 10°Cdp, and even slightly lower with high-quality latent coils. However, caution must be exercised not to push for excessively low dew points, as this can lead to condensate freezing on the coil surface.

For most applications, creating a dew point down to 10°C is considered safe and adequate. Lowering the dew point even further risks the formation of ice on the coil, which acts as a thermal barrier, hindering heat transfer efficiency. Eventually, the coil may freeze up, severely restricting or completely blocking airflow.

In fresh air systems that demand drying beyond 10°Cdp, it has become standard practice to use chilled water (CHW) coils to extract moisture only to that level. The slightly cool, saturated air exiting the cooling coil can then be further dried by passing it directly into a desiccant dehumidifier. This combined approach harnessing both cooling and desiccant technologies enables the production of exceptionally dry air, reaching dew points as low as minus 60°Cdp.

Such a system proves particularly beneficial during the warm and humid summer months when the incoming air requires substantial dehumidification. By using pre-cooling and desiccant technologies in tandem, the system can efficiently produce dry air, ensuring comfortable and controlled indoor environments.

However, during the cooler winter months, when the incoming air is less humid, the pre-cooling system can be disabled, and dehumidification is achieved solely using the desiccant dehumidifier. This adaptive approach optimises energy usage, ensuring the most efficient operation throughout the varying seasons.

As moisture is extracted from the air during the dehumidification process, energy in the form of heat is released into the air. The resulting warm, dry air can be cooled, if necessary, by implementing an additional cooling coil. In this configuration, the cooling coil’s primary function is to control the temperature, with no latent duty involved, as the air has already been effectively dried using the desiccant system.

The combination of desiccant drying with pre-cooling offers a versatile and efficient solution for achieving precise moisture control across various industrial and commercial applications. By using both cooling and desiccant technologies wisely, you can create a comfortable indoor environment with exceptionally dry air during humid periods, while also optimising energy consumption during milder seasons.

-

Dessicant Drying with Pre-Cooling

As with refrigerant cooling, chilled water cooling coils can also be used to remove moisture efficiently down to 10°Cdp. Whenever the inlet condition permits, it makes sense to use cooling coils in addition to the desiccant unit.

It is generally accepted that cooling methods can be used safely to create a dew point down to 10°C. With high quality latent coils, slightly lower dew points could be achieved. This is often unnecessary and risks condensate freezing on the coil surface. Ice creates a thermal barrier that reduces heat transfer efficiency. Eventually the coil will freeze up and impede or totally choke the airflow.

On fresh air systems that require drying below 10°Cdp, it is now standard practice to use chilled water (cw) coils to extract moisture only to that level. Cool, saturated air from the cooling coil can be dried further by passing it directly into a desiccant dehumidifier.

By utilising both cooling and desiccant technologies, very dry air can be produced (as low as minus 60°Cdp).

This system works well in summer when the incoming air is warm and humid.

During the cooler winter months the pre-cooling system is disabled and dehumidification is achieved using the desiccant dehumidifier only.

As moisture is removed, energy is released in the form of heat into the air. The warm dry air can be cooled by installation of another cooling coil, which serves to control temperature only (no latent duty).

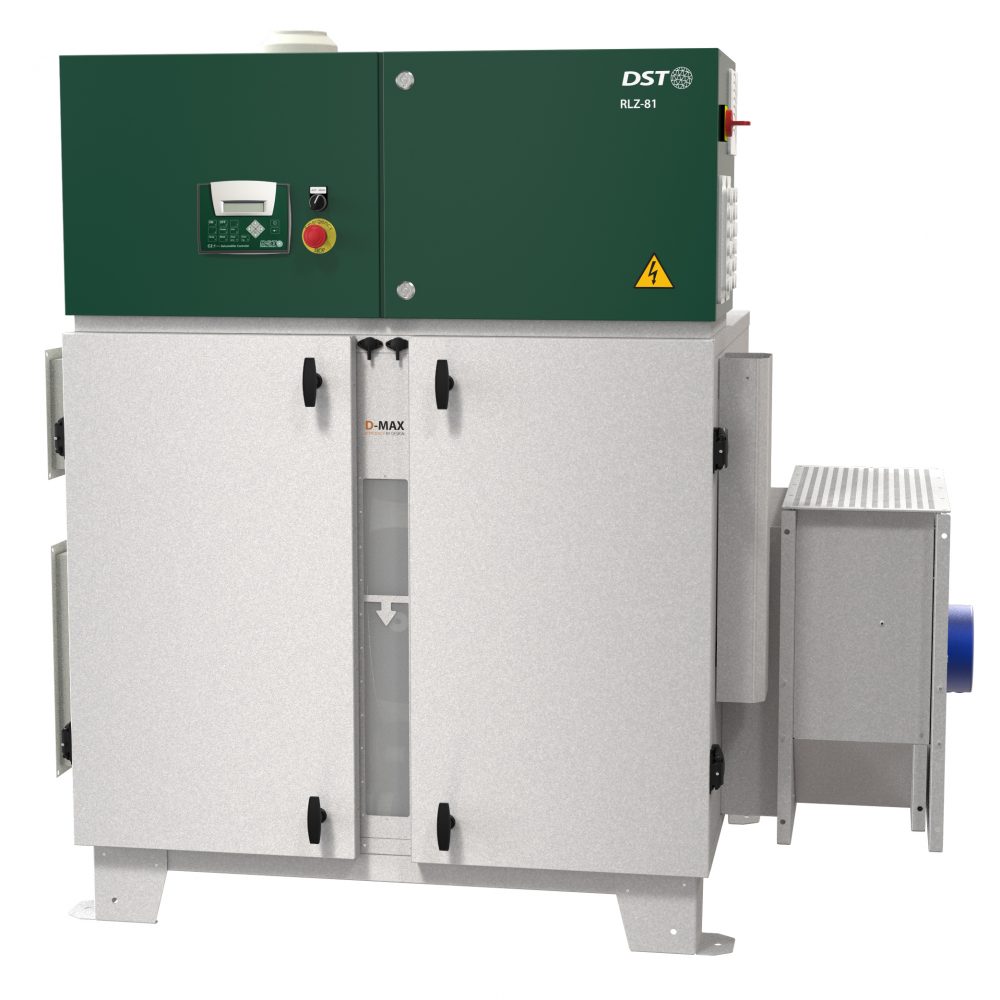

Industrial Desiccant Dehumidifier RLZ & CZ

Industrial Desiccant Dehumidifer Flexisorb

Print Finishing: Maintain the quality and precision of your print finishing processes with our reliable dehumidification solutions. Say goodbye to issues caused by excessive moisture, such as paper curling and ink adhesion problems.

Chemical & Pharmaceutical: In sensitive chemical and pharmaceutical environments, controlling humidity is of utmost importance. Our cutting-edge dehumidifiers create the ideal conditions for critical processes and storage, preserving the integrity of your products.

Medical Scientific: Precision is key in medical and scientific settings. With our industrial dehumidification systems, you can ensure consistent and stable conditions for laboratories, research facilities, and medical equipment storage.

Plastics & Rubber: Excess moisture can wreak havoc on plastics and rubber manufacturing, leading to defects and compromised product quality. Trust our solutions to maintain the right humidity levels, improving production efficiency and end-product consistency.

Engineering & Other Manufacturing: From precision engineering to various manufacturing processes, our dehumidifiers deliver the perfect balance of humidity control, resulting in enhanced productivity and reduced downtime.

Food & Beverage: In the food and beverage industry, maintaining proper humidity levels is crucial for freshness and shelf life. Our solutions ensure that your products remain in optimal condition throughout production, storage, and distribution.

-

R & RL Series Desiccant Dehumidifiers

Introducing R & RL Series Desiccant Dehumidifiers: Versatile Industrial Solutions

The R & RL Series Desiccant Dehumidifiers offer a mid-range solution for a diverse range of industrial applications, providing efficient moisture control and dry air storage. Manufactured using high-quality 2333 stainless steel, these units are built to withstand demanding environments and deliver reliable performance.

Applications:

Dry Air Storage: The R & RL Series ensures the preservation of dry air for various storage needs, maintaining the integrity of sensitive materials and products.

Cold Stores: These dehumidifiers effectively regulate humidity levels in cold stores, preventing frost buildup and ensuring optimal conditions for stored goods.

Sports Halls: In sports halls, the R & RL Series maintains comfortable and conducive environments for athletes and spectators by controlling humidity levels.

Museums: For preservation purposes, these dehumidifiers create stable conditions, protecting valuable artifacts and exhibits from moisture-related damage.

Clean Rooms: The R & RL Series guarantees controlled humidity levels in clean rooms, crucial for maintaining the integrity of sensitive processes and products.

Pneumatic Conveying: These dehumidifiers play a vital role in pneumatic conveying systems, ensuring the smooth and efficient transfer of materials.

Process Air Conditioning Systems: The R & RL Series is adept at controlling humidity in process air conditioning systems, optimising manufacturing, and industrial processes.

Features:

Internal Heat Recovery: These units come equipped with internal heat recovery, enhancing energy efficiency, and reducing operational costs.

Electric Reactivation: The R & RL Series utilises electric reactivation for effective moisture removal, ensuring consistent and reliable performance.

Auto/Manual Mode Switching: With the convenience of Auto/Manual mode switching, users have greater control over the dehumidification process.

Control Options: Pre-wired for two 2-step binary control from the EH4 2-step controller as standard, the units are also available for linear capacity control from the EH3 PI controller or BMS control signal.

D-Max Ceramic-Silica Gel Rotor: The high-capacity D-Max rotor efficiently absorbs moisture, guaranteeing superior dehumidification performance.

Essential Components: The R & RL Series come complete with G4 panel filters, reactivation heater, process and reactivation fans, and all necessary controls for seamless operation.

Steam Reactivation Option: For specific applications, steam reactivation is available as an alternative reactivation method.

The R & RL Series Desiccant Dehumidifiers offer versatile and efficient solutions for a broad range of industrial settings. With their robust construction and advanced features, these units ensure precise moisture control and reliable performance, catering to the diverse needs of various industries. From dry air storage and cold stores to sports halls, clean rooms, and more, trust the R & RL Series to optimise humidity levels and create optimal conditions for critical processes and storage requirements.

-

Flexisorb (RF & CF) – Industrial Desiccant Dehumidification Systems

The Flexisorb range has been meticulously developed to cater to the diverse requirements of the process industry. These compact industrial dehumidification systems offer unparalleled flexibility, designed to meet the specific demands of various applications. At the heart of these systems lies our cutting-edge desiccant rotor, forming the foundation for exceptional performance.

The Flexisorb range includes two distinct configurations, each engineered to address different industrial needs: the ‘Recusorb’ and ‘Consorb’ principles. These configurations provide versatility and efficiency, ensuring that the dehumidification system perfectly matches the intended application. With the Flexisorb systems, achieving impressively low dew points is now a reality. In a single pass, dew points as low as minus 60°C can be effortlessly achieved, setting a new standard in industrial dehumidification capabilities.

Key Features of Flexisorb Range:

Custom-Built Solutions: Flexisorb units are tailored to suit the specific requirements of each application in the process industry. Our team of experts works closely with clients to design solutions that align perfectly with their needs.

Desiccant Rotor Technology: The heart of the Flexisorb range lies in its advanced desiccant rotor. This technology ensures efficient and reliable moisture removal, providing an optimal environment for various industrial processes.

Recusorb Principle: Flexisorb units can be configured using the ‘Recusorb’ principle, catering to specific applications where this approach is best suited. This configuration delivers outstanding dehumidification results with utmost precision.

Consorb Principle: For applications that demand a different approach, the ‘Consorb’ principle is available, providing an equally effective solution that meets unique industrial requirements.

Ultra-Low Dew Points: The Flexisorb range raises the bar for industrial dehumidification, enabling the achievement of dew points as low as minus 60°C in a single pass, guaranteeing superior performance and unmatched results.

To summarise, the Flexisorb range represents a new era of custom-built industrial dehumidification systems, revolutionising the process industry. Whether it’s the ‘Recusorb’ or ‘Consorb’ principle, these compact units are designed to adapt and deliver exceptional results in any application. With the advanced desiccant rotor technology at their core, these systems offer precise moisture control, ensuring optimal conditions for various industrial processes. Experience the power of Flexisorb and elevate your industrial dehumidification needs to new heights.

-

Bespoke Dehumidification Systems

Here at Newsome we take pride in offering industrial dehumidification systems that can be precisely tailored to meet individual requirements. With our standard D-Max silica gel rotor, achieving impressively low dew points of minus 60°C in a single pass is easily within reach. For even lower dew points, our SZCR Zeolite rotor is available, ensuring utmost flexibility to cater to diverse industrial needs.

Our comprehensive range spans from basic desiccant dehumidification solutions to complete climatic control systems. No matter the complexity of your application, Flexisorb delivers efficient and reliable atmospheric air dryers that are designed around the rotor to conform precisely to our customers’ unique specifications.

Dehumidifying air is the central objective of every Flexisorb system. To enhance the overall efficiency of the drying process, pre-cooling of incoming fresh air is often employed. Additionally, we offer the option of including post heating and post cooling features, allowing for precise control of the supply dry air temperature to meet specific requirements.

With the flexibility to handle process air flows of up to 60,000 m³/h, the Flexisorb system stands out as one of the most versatile air drying solutions available today. We pride ourselves on delivering solutions that cater to diverse industrial needs, offering unrivaled performance and reliability.

Key Features of Flexisorb Industrial Dehumidification Systems:

Customisation: Our systems are designed to be fully customisable, ensuring that each solution is tailor-made to meet the exact needs of our customers.

Advanced Rotor Technology: Our standard D-Max silica gel rotor enables efficient moisture removal, while the SZCR Zeolite rotor option allows for achieving even lower dew points when necessary.

Comprehensive Solutions: From basic dehumidification to complete climatic control, we offer a wide range of solutions to suit various industrial applications.

Pre-Cooling and Post Heating/Cooling: To enhance system efficiency and achieve precise control over dry air temperature, pre-cooling, and post heating/cooling features are available.

High Air Flow Capacity: With the ability to handle process air flows of up to 60,000 m³/h, Flexisorb systems offer exceptional performance for industrial-scale dehumidification needs.

In conclusion, Flexisorb takes industrial dehumidification to the next level by providing custom-tailored solutions that precisely match the requirements of each application. With our advanced rotor technology, efficient moisture removal is guaranteed, and our range of options ensures the ability to achieve even the lowest dew points. From basic dehumidification to complete climatic control, Flexisorb offers versatile and highly efficient solutions, making it a top choice for a wide range of industrial atmospheric air-drying needs.

Energy-efficient and Environmentally Friendly

All Flexisorb dehumidifiers are designed to be energy efficient and environmentally friendly. Regeneration heaters are available for use with natural gas, LPG, steam, hot water and electric – or a combination of two.

The D-Max Silica Gel Rotor

The D-Max high-capacity adsorption rotor is at the heart of every DST dehumidifier.

Our silica gel rotors have been a leading light in the field of adsorption technology for many years and offers numerous advantages:- high efficiency, washable, bacteriostatic, non-flammable, non-toxic, environmentally friendly, long service life, high dehumidification capacity & no particulate carry-over.

Optimised Control

All Flexisorb dehumidifiers are designed to be energy efficient and environmentally friendly. Regeneration heaters are available for use with natural gas, LPG, steam, hot water and electric – or a combination of two.

One Unit – One Supplier

We provide the complete solution as a “plug & play” unit. This simplifies delivery, reduces installation time, and eliminates potential demarcation problems at the commissioning stage.

-

Dessicant Drying with Pre-Cooling

As with refrigerant cooling, chilled water cooling coils can also be used to remove moisture efficiently down to 10°Cdp. Whenever the inlet condition permits, it makes sense to use cooling coils in addition to the desiccant unit.

It is generally accepted that cooling methods can be used safely to create a dew point down to 10°C. With high quality latent coils, slightly lower dew points could be achieved. This is often unnecessary and risks condensate freezing on the coil surface. Ice creates a thermal barrier that reduces heat transfer efficiency. Eventually the coil will freeze up and impede or totally choke the airflow.

On fresh air systems that require drying below 10°Cdp, it is now standard practice to use chilled water (cw) coils to extract moisture only to that level. Cool, saturated air from the cooling coil can be dried further by passing it directly into a desiccant dehumidifier.

By utilising both cooling and desiccant technologies, very dry air can be produced (as low as minus 60°Cdp).

This system works well in summer when the incoming air is warm and humid.

During the cooler winter months the pre-cooling system is disabled and dehumidification is achieved using the desiccant dehumidifier only.

As moisture is removed, energy is released in the form of heat into the air. The warm dry air can be cooled by installation of another cooling coil, which serves to control temperature only (no latent duty).

-

RLZ & CZ – Industrial Desiccant Dehumidifier

Introducing Flexisorb Industrial Dehumidifiers for Versatile Applications

Flexisorb presents a range of industrial dehumidifiers utilising cutting-edge desiccant technology, specially designed to cater to a wide spectrum of industries and applications. From chemical and pharmaceutical manufacturing processes to large warehouses, cold stores, ice rinks, and sports halls, our Flexisorb dehumidifiers offer unmatched performance and reliability.

Built with durability in mind, our industrial dehumidifiers are manufactured using Aluzinc, ensuring resistance to corrosion and harsh industrial environments. The Flexisorb range comprises two main series: the Recusorb RLZ units and the Consorb CZ Series, each designed to excel in different applications.

Recusorb RLZ Units:

The Recusorb RLZ units are engineered with internal heat recovery as a standard feature, providing optimal energy efficiency and cost-effectiveness. These units are particularly well-suited for chemical, pharmaceutical, and food manufacturing processes, where precise humidity control is essential for product quality and stability.

Consorb CZ Series:

The Consorb CZ Series is specifically designed for deep drying applications, making them ideal for environments that require exceptional moisture removal capabilities. With these units, you can achieve precise humidity control, ensuring the ideal conditions for critical processes and storage.

Customisable Heating Options:

Flexisorb industrial dehumidifiers offer versatility in heating options to suit different requirements. Choose from electric, steam, direct fired gas, or hot water reactivation heaters, depending on your specific needs and energy preferences.

Comprehensive Package:

All RLZ and CZ dehumidifiers come with an extensive package of essential components. As standard, you will find G4 air inlet filters, process and reactivation fans, a reactivation heater, and the highly efficient D-Max desiccant rotor. Our electric control panel and PLC C2 with a fully integrated capacity control system ensure seamless operation and precise humidity regulation.

Benefits of Flexisorb Industrial Dehumidifiers:

Tailored for Various Industries: Flexisorb dehumidifiers are designed to address the unique requirements of diverse industries, providing precise and efficient humidity control.

Durability and Corrosion Resistance: Manufactured with Aluzinc, our dehumidifiers withstand challenging industrial conditions, ensuring longevity and reliable performance.

Internal Heat Recovery: The RLZ units come equipped with internal heat recovery, enhancing energy efficiency and reducing operating costs.

Deep Drying Capability: The Consorb CZ Series is specially designed for deep drying applications, offering exceptional moisture removal efficiency.

Versatile Heating Options: Choose from multiple heating options to meet your energy preferences and specific needs.

Experience the power of Flexisorb industrial dehumidifiers and optimise your processes with precise humidity control. Trust in our technology, quality, and expertise to elevate the performance and efficiency of your operations across a wide range of industrial applications.

Capacity Control Options

Two-step, multi-step binary or full PI linear control using either EH4, EH3 or an external BMS control signal.

Other Options Include:

- Stainless steel chassis (S2333 or S2343)

- Internal ‘Armaflex’ insulation (19 mm or 32 mm)

- Fan motor frequency inverters

- Inlet bag filters to F7

- SSCR-H or SSCR-Cl rotor

- PLC C4 with Modbus TCP/IP protocol

-

Flex Industrial Desiccant Drying Systems

Introducing Flex Industrial Desiccant Drying Systems – Enhance Your RLZ Series

The Flex Industrial Desiccant Drying Systems are meticulously designed to perfectly complement the RLZ series, providing enhanced capabilities to meet diverse industrial needs. These systems offer convenient bolt-on modules, each tailored to serve specific functions, ensuring optimal performance and efficiency.

Key Modules Include:

Pre-cooling & Post-cooling (Chilled Water): The pre-cooling and post-cooling module utilises chilled water to efficiently cool the air before and after the dehumidification process, ensuring precise humidity control.

Pre-heating & Post Heating (Hot Water & Steam): The pre-heating and post-heating module utilises hot water or steam to warm the air before and after dehumidification, optimising the overall drying process.

Process Fan – Plug Type: The plug-type process fan, directly driven by a 2-pole motor, ensures efficient and reliable airflow within the system.

Filters to F7: The F7 filters effectively remove airborne impurities, ensuring clean and contaminant-free air for industrial processes.

Durable Construction:

The Flex Industrial Desiccant Drying Systems are crafted using sturdy aluminium frames, providing robustness and longevity. The double-skin insulated Aluzinc panels, equipped with 50mm fire-resistant mineral wool (environmental class C4), guarantee enhanced insulation and safety. Each module is independently supported on an Aluzinc frame, ensuring stability and flexibility in system configuration.

Benefits of Flex Industrial Desiccant Drying Systems:

Perfect Complement to RLZ Series: These systems are specifically designed to seamlessly integrate with the RLZ series, enhancing the performance and versatility of your dehumidification setup.

Tailored Functionality: With various modules to choose from, you can customise your drying system to meet the unique requirements of your industrial applications.

Enhanced Efficiency: The pre-cooling, post-cooling, pre-heating, and post-heating modules optimise the drying process, ensuring precise and consistent results.

Clean Air Supply: The F7 filters efficiently remove impurities from the air, providing a clean and contaminant-free environment for your industrial processes.

Durable and Insulated Construction: The robust aluminium frames, double-skin insulated Aluzinc panels, and fire-resistant mineral wool offer longevity, stability, and safety in operation.

Experience the power of Flex Industrial Desiccant Drying Systems and elevate your RLZ series to new heights of efficiency and performance. With customisable modules and durable construction, these systems are the ideal solution to meet the diverse dehumidification needs of various industrial applications. Trust in Flex to optimise your drying processes and achieve precise humidity control in your industrial environment.

-

DC & DR Series Desiccant Dehumidifiers

DC & DR Series Desiccant Dehumidifiers: Industrial Excellence for Diverse Applications

The DC & DR Series Desiccant Dehumidifiers offer a robust range of industrial dehumidifiers, perfectly suited for a variety of applications. From flood and water damage restoration to temporary humidity control, museums, research laboratories, silo headspace conditioning, dry air stores, and small production processes, these industrial dehumidifiers deliver exceptional performance and reliability.

Features and Configurations:

Industrial Strength: Manufactured from durable 2333 stainless steel, these dehumidifiers are built to withstand challenging industrial environments, ensuring longevity and consistent performance.

The DC & DR Series is available in three configurations to meet different application needs – Aquasorb (A30), Consorb (DC), and Recusorb (DR).

All units include our advanced D-Max ceramic silica gel rotor, ensuring efficient moisture removal and precise humidity control. On single-phase units, reactivation heaters utilise positive temperature coefficient (PTC) thermistor technology, providing self-regulation for maximum safety and energy efficiency. Three-phase units utilise resistive type heaters.

These dehumidifiers come equipped with Auto-Manual mode switching, allowing for easy control and operation. Units are pre-wired for convenient humidistat connection via an Amphenol plug, simplifying setup and integration into existing systems.

Versatile Applications:

Flood & Water Damage Restoration: The DC & DR Series efficiently aids in flood and water damage restoration, ensuring quick and effective moisture removal.

Temporary Humidity Control: Perfect for providing temporary humidity control in various environments, such as construction sites, events, and temporary structures.

Museums & Research Laboratories: These dehumidifiers play a vital role in preserving artifacts and maintaining stable conditions in museums and research laboratories.

Silo Headspace Conditioning: The DC & DR Series optimises silo headspace conditions, ensuring product quality and longevity.

Dry Air Stores: For dry air storage requirements, these industrial dehumidifiers maintain consistent humidity levels to protect stored goods.

Small Production Processes: These units are well-suited for small-scale production processes, supporting optimal product quality and manufacturing efficiency.

The DC & DR Series Desiccant Dehumidifiers offer versatile and reliable solutions for various industrial applications. With their robust construction, advanced features, and three different configurations, these units are tailored to suit diverse needs. From flood and water damage restoration to humidity control in museums, laboratories, and small production processes, trust the DC & DR Series to deliver exceptional performance and precise humidity control.

Nationwide Dehumidifier Hire and Rental Solutions

At Newsome, we take pride in offering nationwide dehumidifier hire and rental solutions from our newly acquired 30,000-square-foot facility in Elland, situated midway between Leeds and Manchester in West Yorkshire. With our strategic location close to the main motorway networks, our technical sales, service, and hire teams can respond swiftly to your individual dehumidifier hire requirements all across the UK. Thanks to our extensive network of nationwide support partners, we can cater to your needs at very short notice.

Understanding the criticality of both urgent and planned provision of hire equipment for UK businesses, our specialist hire team is dedicated to delivering exceptional service. Whether it’s an emergency situation or a planned project, our services are available 24 hours a day, 365 days a year, ensuring uninterrupted support for our valued clients.

To guarantee top-tier performance and reliability, we have invested in state-of-the-art ERP 2021-compliant industrial chillers, boilers, heaters, and dehumidifiers. Our equipment is meticulously maintained to the highest industry standards, ensuring it remains efficient and ready for immediate delivery whenever and wherever you need it.

At Newsome, we understand that seamless and reliable equipment is vital to your operations. That’s why our hire solutions are tailored to meet your specific needs, ensuring you have access to reliable and efficient equipment for your projects or emergency situations. Whether you require dehumidifiers for flood restoration, construction, or any other application, we have you covered.

Choose Newsome for nationwide dehumidifier hire and rental solutions that are backed by a team of experts and a commitment to delivering exceptional service. Trust in our industry-leading equipment and responsive support to meet your dehumidification needs, whenever they arise.