The processes used for manufacturing Lithium ion batteries are very similar to those used in the production of Nickel Cadmium cells and Nickel Metal Hydride cells. The anodes and cathodes in Lithium cells are of similar form and are made by a similar process. There are however some key differences associated with the higher reactivity of the chemicals used in the Lithium cells.

The electrolyte filling and sealing stage of cell manufacture must be carried out in a “dry room” since the electrolyte is highly reactive with moisture. Moisture causes the electrolyte to decompose with the emission of toxic gases.

One of the most commonly used electrolyte materials, Lithium Hexafluoride, forms toxic hydrofluoric acid (HF), Lithium Hydroxide and Hydrogen Gas when exposed to moisture.

Crucially moisture sealed inside the battery can continue to react after the battery is completed, significantly reduces its lifespan.

Recent research demonstrates that the ambient moisture present in the manufacturing room can degrade the “memory” characteristic of lithium and the newer advanced polymer-based batteries.

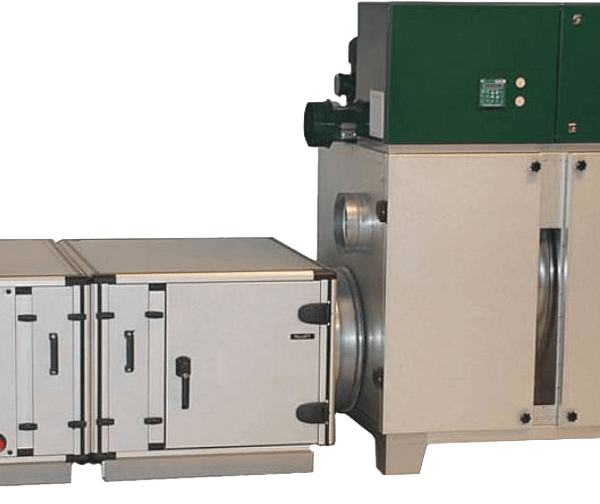

The construction method and design philosophy of the climate control system and dry room are crucial to achieving and maintaining a stable low relative humidity. The dry room and climate control equipment should be designed to achieve:-

- ISO Class 6/7 with volumetric air change rates ranging from 60 to 240 per hour with a uniform air flow

As close to near vapour tight construction as practicable - Supply air of less than -60°Cdp (0.006 g/kg) with return air of less than -40.0°Cdp (equivalent to less than 0.5% RH at 22.0°Cdb) in order to achieve optimal conditions

- Access to the space via ante room and air-lock air showers

- Optimised fresh air introduction to clean room for operators and positive pressurisation