Overview

Client: – UK Leading Estates Management Company

Industry: – Supermarket (end user)

Presence: – 500 stores throughout UK

Project Overview: – Bringing a redundant chilled store back into operation.

Project Value Range: – £500,000 – £750,000

When confronted with the challenge of bringing a redundant chilled store back into operation, a leading provider of real estate solutions sought the expertise of Newsome, to deliver a suitable cooling package for their client, a leading UK supermarket. This case study highlights how Newsome successfully designed and implemented a cutting-edge cooling system installed for the supermarket, exceeding client and end user expectations and revitalising the dormant facility.

Background:

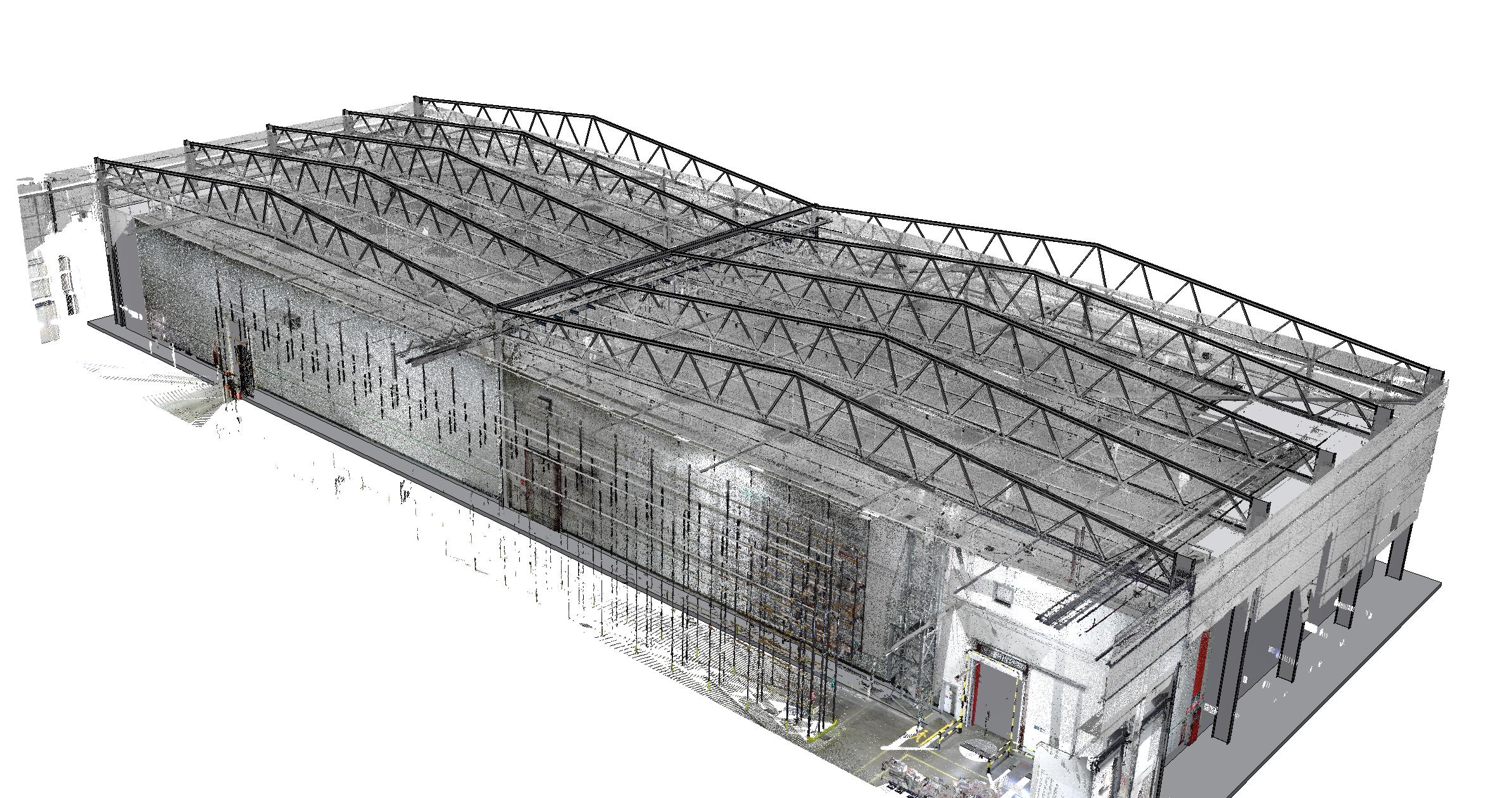

The client approached Newsome with a pressing need to revive an existing chilled store for a leading UK supermarket, which had become redundant due to outdated cooling equipment. The obsolete plant was no longer capable of maintaining the desired temperature of 4°C, posing a significant obstacle to the property’s functionality. Recognising the importance of restoring the chilled store to operational status, Newsome embarked on a mission to design and supply a modern cooling system tailored to the client’s specifications.

Objectives:

The primary objective was clear: to design and supply a cooling system capable of maintaining a set-point temperature of 4°C within the chilled store. However, Newsome aimed to achieve more than just functionality. They sought to deliver a solution that prioritised energy efficiency, reliability, and sustainability, aligning with the client’s commitment to excellence in real estate management.

Proposed Solution:

Newsome Ltd provided cost estimates for the installation of stainless steel thin-walled pipe work to connect the cooling circuit as outlined in the drawings. This included the provision of various components, such as butterfly valves, flexible bellows, binder test points, non-return valves, strainers, pressure gauges, drain points, and an integrated pressurization set with an expansion vessel. Several assumptions and allowances were made during the project planning, including the offloading and positioning of proprietary items by others, the provision of valves by the client, jackpad feet for levelling, and the absence of support blocks unless otherwise stated.

Newsome proposed a comprehensive solution encompassing the design, supply, and commissioning of a new chiller and ceiling-mounted Air Handling Units (AHUs). The design parameters, including room dimensions, ambient temperature, and cooling duty requirements, were carefully considered to ensure optimal performance. Based on preliminary data, Newsome recommended the installation of 10 roof-high level mounted evaporators and a single packaged chiller unit to meet the cooling duty of 497 kW. The selected equipment, including the RTAF205 SE SN air-cooled chiller, was chosen for its flexibility, eco-friendliness, and wide operating range.

Key Features of Selected Equipment:

The RTAF205 SE SN air-cooled chiller offered ultimate flexibility, with various configurations available to suit different applications. It was eco-friendly, utilising R513A refrigerant with a low Global Warming Potential (GWP) value, aligning with sustainability goals. Additionally, the chiller’s wide operating range ensured reliable performance in diverse ambient conditions, while its robust design and dual independent refrigeration circuits enhanced resilience and reliability.

Recommendations and Refrigerant Choice:

Newsome recommended R513A refrigerant for the chiller, considering its low GWP value and long-term suitability. This choice reflected Newsome’s commitment to environmental sustainability and compliance with future regulations. R513A offered a significant reduction in GWP compared to traditional refrigerants like R134A, without compromising performance or efficiency.

Technical Specifications and Performance Data:

The Trane RTAF 205 SE SN EC chiller boasted impressive performance metrics, including a nominal cooling capacity of 497.70 kW and an Energy Efficiency Ratio (EER) of 2.7 kW/kW. Its compact design and advanced features made it an ideal choice for the client’s cooling requirements.

Fan Coils and Additional Recommendations:

Newsome recommended 10 CCZ 20-4 low-temperature fan coils to complement the chiller and ensure uniform cooling within the chilled store. These fan coils offered efficient cooling capacity and precise temperature control, enhancing occupant comfort and energy efficiency.

Mechanical Installation Process:

Newsome meticulously planned the mechanical installation process, ensuring seamless integration of the new cooling system into the existing infrastructure. This involved the installation of stainless-steel pipework, mounting evaporators, and coordinating with other trades to facilitate a smooth implementation process. All installations adhered to industry standards and best practices, with careful attention to detail to minimise downtime and disruptions.

Commissioning and Quality Assurance:

Following installation, the equipment underwent rigorous commissioning by Newsome’s service engineers to ensure optimal performance and reliability. This comprehensive quality assurance process included system testing, performance validation, and client training to familiarise stakeholders with the new cooling system.

Conclusion:

By partnering with Newsome and embracing cutting-edge cooling technology, the leading provider of real estate solutions successfully revitalised the redundant chilled store for this major supermarket, achieving optimal performance, energy efficiency, and sustainability. The seamless integration of modern equipment, combined with meticulous planning and execution, underscored Newsome’s commitment to delivering tailored solutions that exceed client expectations.