When evaluating which cooling product is suitable for your process the delivery temperature required and footprint are key considerations.

Newsome have the technical understanding and wide range of products available to ensure we can provide the appropriate cooling solution for your business.

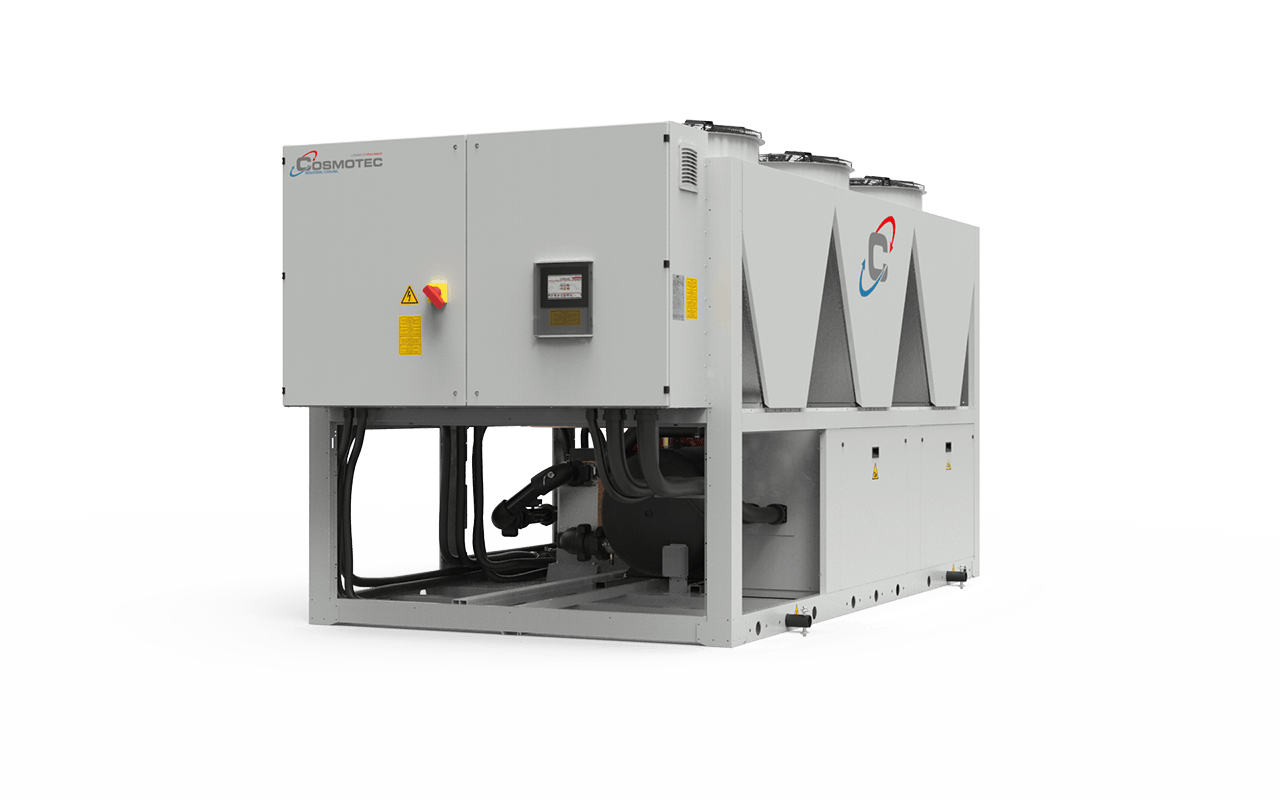

What is an industrial chiller?

Industrial water chillers are used in a variety of applications where chilled water or fluid is circulated through process equipment. They are characterised by an immediate response to changing load requirements, the ability to modulate their cooling capacity, high control accuracy and reliability even within the limits of their operating conditions.

Industrial chillers are commonly used to cool products and machinery in a multitude of different applications including injection moulding, machine tools, lasers, food, beverage, semi-conductors and more.

Free Cooling is a fast and effective way to reduce both energy costs and carbon footprint on refrigerated, process water cooling applications. Depending on the external air temperatures and the temperature desired, chillers can typically be partially or fully offloaded for up to 90% of the year.

Free coolers provide an alternative solution to traditional air-cooled chillers by utilising external fresh ambient air to provide partial or 100% free cooling. They ultimately provide a far more energy efficient and cost- effective way to provide chilled fluid to their processes, to maintain optimum cooling temperatures.

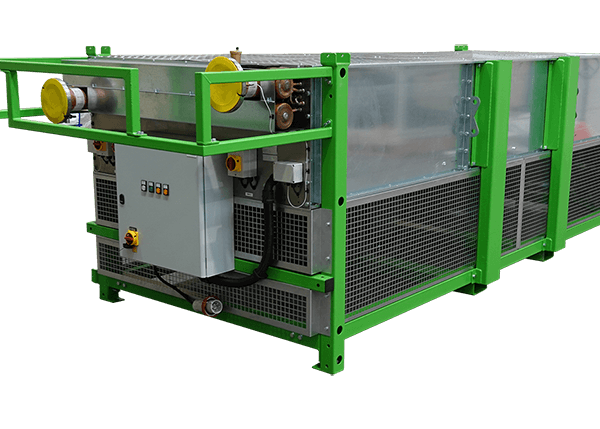

A Dry Air Cooler (DAC) can supply temperatures between 3*C – 5*C higher than the ambient air temperature in which they sit, whilst Adiabatic Coolers can provide supply fluid temperatures around 3*C below ambient.

Ambient coolers if applied correctly can provide a very cost effective & energy efficient temperature control solution.

Newsome’s dry air coolers are built bespoke to customers needs, although the range covers between 42kW – 3mW

Contact us to find out more about our range of industrial dry air coolers.

Adiabatic coolers are a modern alternative to traditional cooling towers, involving significantly lower maintenance and OPEX.

- Modern, low risk alternative to hybrid and traditional cooling towers

- UV sterilisations as standard

- Developed in conjunction with advice given by British Health and Safety Executive

- Minimal water consumption. Less than 4% of Hybrid Cooling Tower and less than 1% of traditional Cooling Tower water usage.

- Extremely Energy Efficient. Variable speed EC and AC fan technology – typically only 25% of traditional fan energy usage.

- Low Legionella Risk. No ongoing chemical treatment or registration with local authorities required.